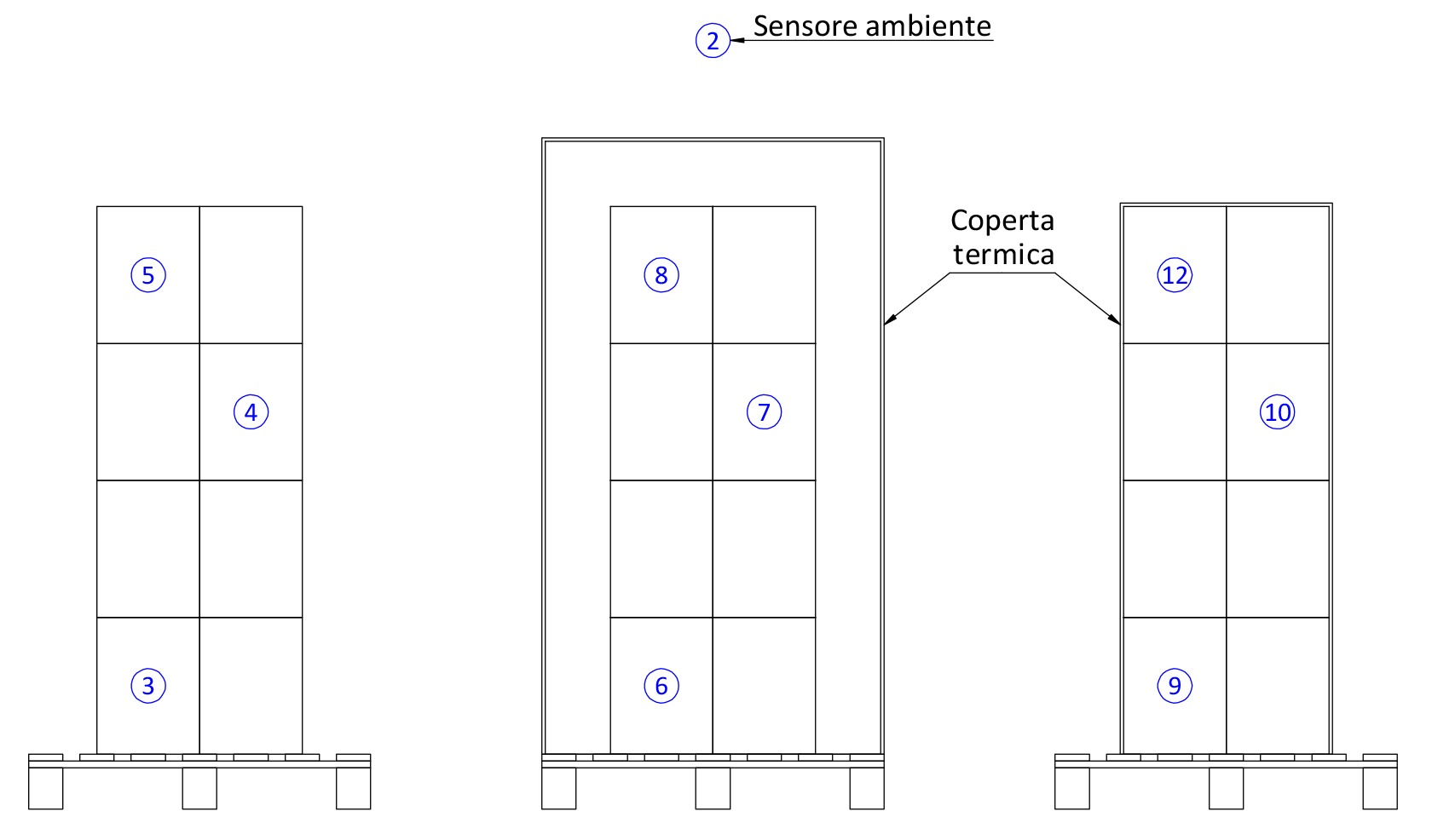

Our Vacool® thermal blanket is made with a pure aluminum foil that shields its contents from the sun’s rays and provides a barrier against thermal changes, as well as against dust and atmospheric agents. Inside it has a layer of bubble wrap, creating an additional air cushion that slows down the heat exchange with the outside and guarantees protection from impact. Specially designed for air and road transport, it is particularly suitable for protecting perishable goods during their transhipment.

The resealable base is also optional, which further reduces the risks due to parking on the Tarmac by protecting from the direct heat of the asphalt.